Keeping Your Rescue Hoist Mission Ready

If your helicopter uses a rescue hoist in some missions and you are responsible for maintaining it, read on. If your helicopter does not have a rescue hoist so that there is no maintenance to be performed, read on anyway, as this is good maintenance information that might prove invaluable to you down the road.

As a helicopter maintenance professional, you might have spent time inspecting and maintaining rescue hoists in your career. Maybe now it is a regular part of your job. While there are many different types of hoists and the components therein, they basically all work the same and have similar maintenance needs and issues. Some of the information that follows might be more specific in nature regarding a particular brand or type of rescue hoist, while other information is more generic and is appropriate no matter what type of hoist you are using.

Helicopter rescue hoists generally have a motor, control, drum, cable and hook. All the related subsections have basic maintenance needs and inspections to be done daily, monthly, annually and after specific mission use. We are not going to get into all the details here, but will cover some little-known tips and ideas that will help you get the most out of your hoist and help prevent unnecessary breakdowns and related service needs.

Tip No. 1: Alignment

Let’s start with the cable drum and cable removal. Typically, when you run the hoist full out to enable removal of the cable, there will still be three or four wraps of cable around the drum. There is a procedure for working this, so please follow the manufacturer’s recommended steps. One thing that is crucially important during a cable removal is that once you fully remove the cable, do not run the hoist or rotate the drum. The alignment of the drum to the level wind shaft is precision synchronized. Any shift in rotation without the cable in place will alter the timing and completely throw off the level wind shaft, in addition to the switches and sensors of the cyclocentric.

The cyclocentric controls the slow-speed zones, full out cable length and other critical controls for the hoist. Think of it this way: if you removed the distributor from your car’s engine, and then put it back with a tooth or two off, everything would be out of sync and the timing would be way off. It’s the same thing on a rescue hoist. Timing and synchronization are crucial to proper and safe operation, and are not areas where you want to have issues. If the timing and synchronization are severely disrupted, it will require factory rework and recalibration of the hoist, causing downtime and added costs to correct the issue.

Tip No. 2: Spring Compression

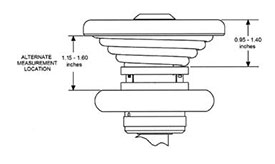

Another simple yet important safety procedure is called “homing the hook.” This is merely retracting the cable and hook into the hoist with enough pressure to ensure that the hook does not freely swing or move when the hoist is “full in.” Each spring bumper type will have a specific compression measurement. In the case of our example, the full-in spring compression should be 0.95 – 1.40 inches. This holds the hook in place and prevents what we call work hardening or premature fatigue of the cable at the hook connection. If the hook is not homed properly, it can swing back and forth, causing the cable to wear as the helicopter is flying. This weakens the cable to the point where breakage and/or separation could occur while in use. Another way to look at it is if you took a paperclip and repeatedly bend it back and forth until it breaks — not a scenario that you want to play out on a rescue hoist.

Tip No. 3: Cleaning the Hook

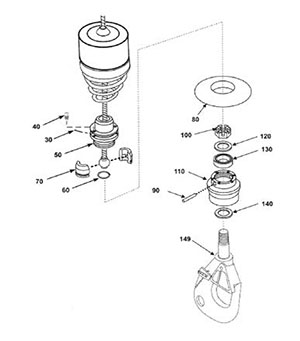

While we’re on the subject of the hook itself, keeping the hook swivel bearings clean helps prevent premature wear, and needs to be done to keep the hook in top functioning order. A simple check rotating the hook body with one finger will ensure that the hook swivels freely and does not bind. If a binding situation is encountered, it can usually be resolved by cleaning and re-greasing the hook bearing. In a rescue scenario, the rotor wash from the helicopter causes the load on the hook to rotate as it nears the aircraft. If the hook does not swivel properly and binds up during a rescue, the cable itself could start twisting and cause premature cable looseness. All it takes is a quick check and a simple step to alleviate the issue.

Tip No. 4: Grounding Cable Cutter Cartridges

Our last quick tip has to do with the cable cut cartridge and related maintenance. Anytime you have the hoist off the helicopter for maintenance, please take the extra precaution of removing the cartridge-grounding plug from the cable cut mechanism. This will prevent an accidental firing of the cartridge (or the curious push of the cable cut button by an unenlightened colleague), resulting in the cable being cut and a replacement then becoming mandatory.

While these tips might sound like basic common sense and easily implemented, we have fielded many calls and have seen many hoists come in for additional repairs due to issues like these. If you’re interested in learning more about rescue hoist maintenance and tips from the experts, you can contact our training department for details on our flight line safety and maintenance training course by calling (973) 602-1001 or signing up via our Web site at www.breeze-eastern.com.

James Fett is the director of training and technical support at Breeze-Eastern, a helicopter hoist and winch provider.

Patrick Doyle is a customer support engineer there.